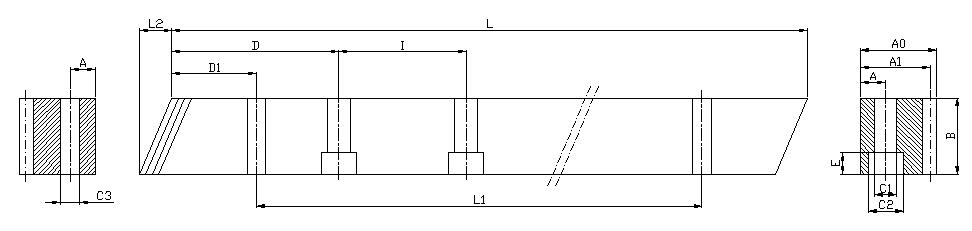

|

Module |

L |

L2 |

Tooth No. |

B |

A0 |

A1 |

D |

I |

Hole No. |

A |

C1 |

C2 |

E |

D1 |

I1 |

C3 |

Pitch Error /300mm |

|

1 |

1000.00 |

3.14 |

300 |

15 |

15 |

14 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.02 |

|

1.5 |

1000.00 |

6.7 |

200 |

19 |

19 |

17.5 |

62.5 |

125 |

8 |

8 |

7 |

11 |

7 |

31.7 |

936.6 |

5.7 |

0.03 |

|

2 |

1000.00 |

8.5 |

150 |

24 |

24 |

22 |

62.5 |

125 |

8 |

8 |

7 |

11 |

7 |

31.7 |

936.6 |

5.7 |

0.031 |

|

2.5 |

1000.00 |

8.5 |

120 |

24 |

24 |

21.5 |

62.5 |

125 |

8 |

9 |

7 |

11 |

7 |

31.7 |

936.6 |

5.7 |

0.033 |

|

3 |

1000.00 |

10.3 |

100 |

29 |

29 |

26 |

62.5 |

125 |

8 |

9 |

10 |

15 |

9 |

35.0 |

930.0 |

7.7 |

0.035 |

|

4 |

1000.00 |

13.8 |

75 |

39 |

39 |

35 |

62.5 |

125 |

8 |

12 |

10 |

15 |

9 |

33.3 |

933.0 |

7.7 |

0.038 |

|

5 |

1000.00 |

17.4 |

60 |

49 |

39 |

34 |

62.5 |

125 |

8 |

12 |

14 |

20 |

13 |

37.5 |

925.0 |

11.7 |

0.04 |

|

6 |

1000.00 |

20.9 |

50 |

59 |

49 |

43 |

62.5 |

125 |

8 |

16 |

18 |

26 |

17 |

37.5 |

925.0 |

15.7 |

0.042 |

|

8 |

1000.00 |

28.7 |

36 |

79 |

79 |

71 |

60 |

120 |

8 |

25 |

22 |

33 |

21 |

120.0 |

720.0 |

19.7 |

0.045 |

|

10 |

1000.00 |

35.11 |

30 |

99 |

99 |

89 |

62.5 |

125 |

8 |

32 |

33 |

48 |

32 |

125.0 |

750.0 |

19.7 |

0.052 |