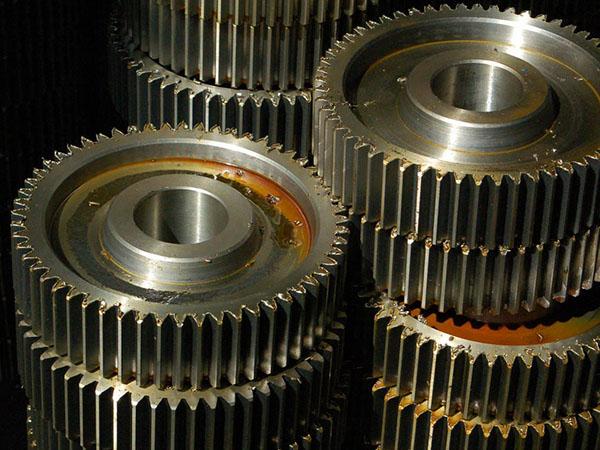

Product Specifications:

|

Material |

C45,1045,42CrMnTi,20CrMnTi,2HT200,HT250,QT400-18,QT400-15,Acetal/Delrin,Alloy,Steel,Aluminum,Brass, Bronze, Carbon Steel, Ductile Iron, Gray Cast Iron, Nylo, Plastic, Phenolic, Polycarbonate, Polyester, Stainless Steel etc. |

|

Modulus |

0.5-24 |

|

Accuracy |

DIN Class 6, ISO/GB Class 6, AGMA Class 13, JIS Class 2 |

|

Standard |

DIN, ISO/GB, AGMA, JIS |

|

Heat treatment |

Quenching and tempering, gear teeth induction quenching, nitriding, carburizing |

|

Application |

automotive, electronics, textiles, printing, packaging, medical equipment, food processing ,wind power, chemical, and pneumatics |

|

Shaft length |

Max 1600mm. |

Capabilities of Gears

|

Item |

Internal Gears |

External Gears |

||||

|

Milled |

Shaped |

Ground |

Hobbed |

Milled |

Ground |

|

|

Max O.D. |

1600mm |

|||||

|

Min I.D.(mm) |

30 |

320 |

20 |

|||

|

Max Face Width(mm) |

500 |

1480 |

||||

|

Max DP |

1 |

1 |

1 |

1 |

||

|

Max Module(mm) |

26 |

45 |

26 |

45 |

||

|

AGMA/ DIN Level |

DIN Class 8 |

DIN Class 6 |

DIN Class 8 |

DIN Class 6 |

||

|

Tooth Finish |

Ra 3.2 |

Ra 0.6 |

Ra 3.2 |

Ra 0.6 |

||

|

Max Helix Angle |

±22.5° |

±45° |

||||